What Does Process Management Actually Involve?

Process management is the structured analysis and optimisation of end-to-end business activities to ensure efficiency, quality, and alignment with strategic goals. It provides transparency about how work flows through your organisation and identifies opportunities for simplification and automation.

Customers demand shorter development cycles, higher product variety and seamless service interactions. To remain competitive, organisations need structured, reliable processes that deliver quality — every time.

Dreher Consulting’s process management services begin with documenting current processes, identifying bottlenecks and inefficiencies, and prioritising improvements based on business impact. We then support the design and implementation of refined processes with measurable KPIs so that operational improvements are sustained over time.

How Can Effective Process Management Deliver Measurable Benefits?

Strong process management helps organisations:

-

Reduce cycle times and operational complexity

-

Improve quality and reduce error rates

-

Enable clearer decision-making through transparency

-

Support automation and digitalisation efforts

-

Strengthen governance and control over operations

These benefits translate directly into cost savings and better business outcomes.

How Does Dreher Support Process Management Success?

Dreher Consulting combines analytical rigour with practical implementation support to improve how your organisation works. Our process management services include:

Bottleneck and root cause identification: Find and prioritise improvement targets

Process redesign and optimisation: Define more efficient flows

Performance measurement framework: Establish KPIs and dashboards

Implementation support: Guide changes and support adoption

Watch on YouTube

What is required of IT in process management?

The requirements are diverse and include topics such as;

-

Supporting customer processes with ERP software

-

Displaying real-time information wherever it is required

- Fast support of new organizational models and processes through software that can easily adapt to new challenges.

- Supporting users through ongoing training, etc.

- Ensuring the integrity of data security

- Ensuring IT security

- Adherence to compliance rules within the framework of legal regulations and the GDPR

How is process management defined? 4 central building blocks.

This translates the company's organizational strategy into process management requirements. This is intended to ensure that the objectives of the corporate strategy can be achieved. The focus here is on determining which processes are core processes and which are support processes. This is described and justified in text form in process management.

What should be considered in strategic process management?

Strategic process management helps to define the long-term orientation and implementation of process optimization initiatives in organizational terms. This prevents process management from losing momentum and falling asleep over time. You anchor your process management in the organizational structure and at the same time define the key performance indicators that monitor the effectiveness of process management.

In operational process management, the central core processes are defined and described during implementation and realization. We also recommend defining key process indicators. This allows you to measure the effectiveness of process improvements. Simple key figures such as throughput time, process deviation (frequency), necessary manual interventions through to individual control variables that are important for your customer process are possible. Only by measuring process quality can you generate the necessary management information in process management. This helps to achieve operational goals. Analyses and data collection from quality management are often used for this purpose and presented in a comprehensive dashboard in process management.

All activities involved in the analysis, evaluation and documentation of process improvements can be found here. This also includes meetings of all participants on the status of process management as a whole. The evaluation of achievements, the determination of which additional information or which data must be recorded are also part of technical process management.

Process management in the context of IT considerationcomprises 2 areas:

Area 1: the performance of the IT organization and the IT service itself.

Area 2: Process management through the use of IT as a data processing tool and for collecting information. Process management is also used in IT to provide key figures so that the performance of IT can be assessed.

Active and effective process management (process management methods) will challenge the performance of the IT department in the face of digitization and digital transformation requirements. The conversion of analog to digital processes usually leads to cost reductions and thus to improvements in competitiveness. Process management is therefore being used more and more in larger organizations. It is not uncommon for organizations or companies that deal with process management to increasingly define positions such as head of IT (CIO) or head of digitalization (CDO) at management level.

What can process management be used for profitably?

Under the impression and perception of constantly changing customer expectations, business models must be redeveloped.

The key points of new business models are

-

Customer orientation

-

Agility

-

Digital processes

Where can process management be successfully implemented in a company?

In many manufacturing and trading companies, logistics is increasingly determining the success of a company. It is not only the customer-optimized services or attractive products, but the overall package in the end-to-end process - from order to payment - that determines whether a company is successful in the eyes of the customer or not.

The entire inbound and outbound logistics process is considered and optimized by modern process management, which naturally includes process optimization in complaints handling. In such cases, process management considers process optimization from the notification of the complaint to the credit note to the new delivery and the verification of whether the customer has received satisfactory support.

Process management within a supply chain encourages and requires companies at all levels to become increasingly networked. Industry 4.0 requirements as a driving force for new technologies, networking and automation affect all companies involved in the supply chain. To avoid being classified as a "commodity" service provider or supplier to the customer, it is important to consistently take the step towards process management.

The ideas of the smart factory are being applied more and more. One keyword here is the ability to produce the so-called "digital twin" before production takes place.

Mass customization and production in batch size 1 are further buzzwords that can only be implemented competitively at a high-wage location with excellent process management.

This also includes the ability to deal with generated data, analyze it and derive actions for management from it.

Reference models from production also serve this purpose, as they can provide an indication of where and how best practice can be used.

The concept of administration applies to both the administration of a company and the administration of the public sector.

In both administrations, process management is a possible procedure for defining workflows, automating processes and reducing system breaks. This usually includes issues relating to

- document management,

- archives,

- resubmissions,

- DSGVO through to

- personnel files and

- application management

are related.

We are currently experiencing an enormous acceleration in networking and cooperation via the Internet. In many areas, this is leading to new processes and structures for obtaining and passing on information.

As a result of the increase in these networks, the complexity of processes is also increasing and uncertainties are generally on the rise (management by sight as a keyword). This is another important reason why the importance of business processes will continue to increase. They define the rules and procedures and also allow the necessary tolerances and freedom for direct decisions that may have to be made by employees for customer processes.

It is very important to ensure that process management is geared towards these new challenges, such as delivering faster value propositions and greater flexibility in the provision of customer services.

This also applies to the requirements for improving customer orientation.

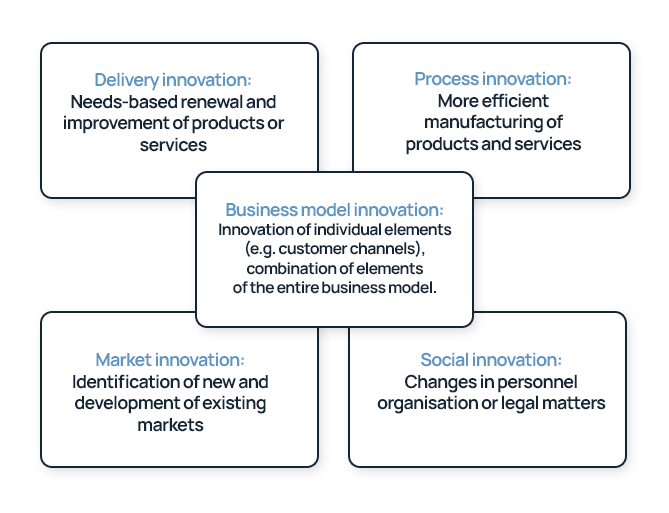

Sub-areas of business model innovation

-

Delivery innovation: Demand-oriented renewal and improvement of products or services

-

Market innovation: Identification of new and development of existing markets

-

Process innovation: More efficient production of products and services

-

Social innovation: Changes in personnel, organizational or legal areas

What do you get from us?

- An analysis of your status quo

- Identification and documentation of optimization potential for your processes

- IT audits

- Creation of an implementation and project plan

- Project management and monitoring of the implementation of process optimization

- Definition and tracking of KPIs

What else you should know about process management

As globalization continues to advance and the supply chain is optimized, companies are constantly being forced to further optimize their processes in a highly competitive environment.

One keyword here is theacronym VUKA, short for:

- V= Volatility

- U= Uncertainty

- K= Complexity and

- A= ambiguity (ambiguity)

The constant competitive pressure and the inevitable need to adapt processes also lead to uncertainty, both for the companies and employees concerned and for the responsible management (the keyword here is - corporate management by sight), which is repeatedly communicated in press conferences and statements by company managers.

In business practice - as well as in traditional business and organizational theory - the approach of a functionally structured organization dominates. Functional specialization makes it possible to develop many advantages, for example the rapid learning effects during training. The development of special tools and special machines just for this one operation has its origins in this idea and has brought enormous efficiency gains for everyone involved.

However, the functional organizational model also generates problems that need to be solved. Customer-oriented value creation (value stream) usually runs across several functional organizational units. People also like to talk about a so-called "silo organization", in which a customer process meanders vertically up and down the company several times until it eventually leads to a value stream of a product or service for which a customer is willing to pay.

A customer, however, usually travels "horizontally" across the entire breadth of the company and receives services from the sales, production, shipping and logistics departments, as well as the finance department in the context of invoicing and payment settlement.

The widespread functional organizational models and organizational structures are usually organized vertically within the framework of authority and work really well. Coordination on a horizontal level is much more difficult because the organizational boundaries usually have to be overcome for process orientation. Who hasn't experienced it: different views between sales and production, logistics in turn has different ideas about promises made by sales and production struggles with sales promises and logistical challenges regarding delivery dates or costs.

Individual process optimizations that are limited to specific functions can also be counterproductive in the overall value creation process. Not every (partial) optimization is a gain in the overall customer process, but can also paralyze it (assuming departmental thinking).

Therefore, systematic process management along a customer process is the decisive initiative to realize a competitive advantage.

One of the reasons for the "yo-yo" effect that can be observed time and again when using process optimization is that the focus tends to be on the "previous, preserved" functional processes. Minor improvements are certainly better than no process improvements. Nevertheless, we experience time and again that participants in a process optimization initiative lack the courage to completely rethink and discuss the "green field approach".

At the same time, it can also be seen that the use of systematic process management for process optimization is also experiencing fluctuations in attention. For this reason, studies (such as the BPM Compass) have also confirmed that the intensity of use can fluctuate depending on the strategic focus of the company.

Process optimizations were usually started as self-contained projects.

This worked well in itself, but with increasing use and experience it quickly became clear that this was not necessarily associated with sustainable process improvement.

After a few years of dealing with the re-engineering of processes, many companies have moved away from this radical approach and are once again focusing more on approaches that enable incremental optimization. This was to ensure that processes could meet the requirements of customer processes in the long term and that the employees involved also supported the organizational changes.

At the same time, a so-called process owner was installed in many cases. Mostly experienced users who were able to oversee and manage a horizontal process flow. (Mostly end-to-end processes). These process owners are extremely important and play a decisive role, especially in projects where new IT or ERP software is to be introduced at the same time.

In process optimization initiatives, we often see that the initiative or project is very strongly defined by basic methods or, even worse, by corresponding business process management (BPM) tools and software tools. Depending on the existing IT orientation, classic visualization programs and even serious tools were used.

Now and again, this may be understandable in the justified approach of avoiding a proliferation of tools. However, not every tool works and is useful for every issue. Above all, professional BPM tools also require appropriate user expertise. The notation associated with these tools, such as EPC (event-driven process chain, which was used in the ARIS/von Scheer model) or BPMN notation, is anything but self-explanatory. This means that the tool itself can often be an obstacle and lead to worse results than expected. Furthermore, it is not easy to prepare the results of such a notation for management levels that do not work with these tools on a daily basis.

To circumvent these problems, classic presentation programs were sometimes used to draw the processes.

The changes in the environment and competition of companies have led to the importance of process organization and thus also the design of business processes becoming more important. The demands on process management have increased for the following reasons:

Internationalization requires new processes and fiscal adjustments in the context of tax requirements of individual countries.

The rapid development of information technology means that the factors of time, price, flexibility, quality and service have become decisive competitive differentiators.

What does this mean as a consequence?

The organizational structures of a company must therefore be primarily aligned with the horizontal perspective (the process organization).

This was also documented in a study by Harvard professor Alfred D. Chandler, who formulated it as follows: "Structure follows process follows strategy"

This study examined how companies adapt to changes in the environment in order to continue to ensure the efficient use of resources.

The concept of the value chain was first published by Harvard Business School Professor Michael E. Porter in 1985 in his book "Competitive Advantage". The processes were broken down into primary and secondary processes. The entirety of the processes enables the company to create value. Primary processes create value directly, secondary processes provide support and therefore create value indirectly.

The idea discussed in recent years of the core business on which a company should concentrate has led to the terms "extended workbench" or "outsourcing" gaining in value.In many companies, services are no longer all provided in-house. Instead, contract steps are outsourced to value creation partners , meaning that individual companies are embedded in one or more cross-company value chains. This can be a national or international network. This can go so far that value creation partners have specified suppliers (OEMs) manufacture final products in terms of design and product names.

This means that individual companies are no longer in competition with each other, but rather entire value chains. It is therefore important for competitiveness that process management considers the entire value chain: the supply chain.

Process management methods for modeling

The EPC is one of the best-known types of process modeling. This method was developed under the direction of Professor Scheer at Saarland University on behalf of SAP in 1992. This process model became known as part of the Architecture of Integrated Information Systems (ARIS). It was based on Petri nets. These were extended to include symbols and semantics, so that today it is known as the extended event-driven process chain (eEPK). Complex processes can be mapped by stringing together functions and events.

The Unified Modeling Language was created back in 1990 and has been continuously developed further. UML is based on an object-oriented view. Objects are extracted from real business processes, assigned specific attributes and described. Several similar objects are combined into classes. This turns classes into blueprints of the objects to be created. The basis for the diagram types in UML are object, class, attribute and method. Static and dynamic models can be developed.

BPMN (Business Process Model and Notation)

The Business Process Model and Notation has become a quasi-standard for modeling business processes. It is often simplified and used colloquially as BPM. BPMN focuses on the graphical representation of business processes in process management. The comprehensibility of the models should help to present technical issues in a simple and understandable way.

There are different types of diagrams.

One type of diagram is the business process diagram, whose elements can be divided into 4 groups.

- Flow elements (flow objects)

- Artifact elements (artifacts)

- Connection objects and

- Partitions (swimlanes)

Swimlanes can be used to divide business processes into areas of responsibility (business areas/departments). The process elements of the BPMN are similar to the elements of the EPC. However, BPMN is easier to use as it does not use the restrictions of EPC.

Ready to Strengthen Your

Digital Strategy?

Talk to an expert today and get clear guidance for your next steps.